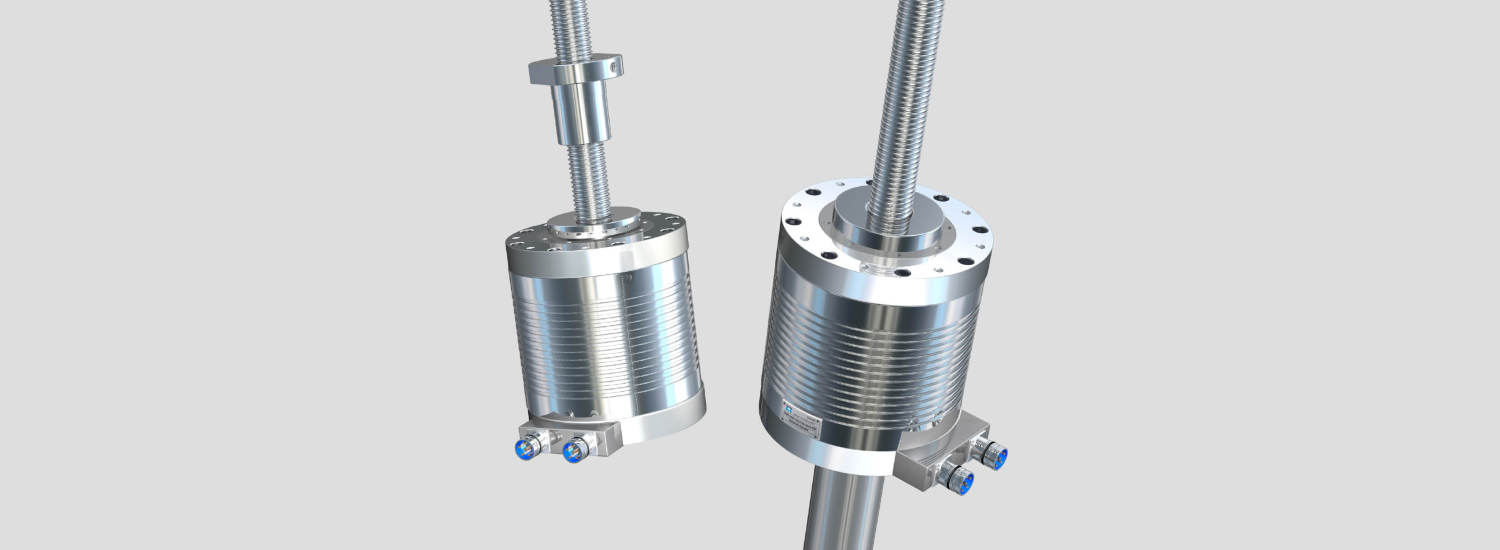

DSH Screw Jack

Direct-Drive with integrated Torque Motor

PRODUCT

A classic spindle screw jack consists of one or several worm gears, that as a rule are driven by one drive motor. As a result very long drive trains can develop, which lead to greater mechanical losses when only one motor is used.

For particular applications with high clock frequencies in combination with a high duty cycle conventional screw jacks using worm- or bevel-gear units are often pushed to their limits. Those are two of many reasons for the development of a completely new screw jack system. Following extensive preliminary investigations with the involvement of technical universities our new direct spindle screw jack (DSH) was developed.

INKOMA-DSH screw jacks work without a separate gear unit. A ball screw is integrated directly in a torque motor. Consequently the ball screw drive is driven directly and without play by the motor. As a result almost no mechanical losses develop in the complete DSH system. Pull- and push forces of the spindle are absorbed via corresponding axial bearings. The compact drive system is distinguished through a high degree of rigidity and is therefore suitable for highly dynamic applications. Lift clock frequencies in the Hertz range can be achieved at travel speeds from standard up to 32 m/min. Thereby the positioning- and repeat accuracy is in the micrometer range. Multiple drives working together do not need to be placed in one plane. Nevertheless they work exactly synchronously with each other.

PRODUCT MOVIE

Contact

INKOMA Maschinenbau GmbH: info@inkoma.de

Maschinenfabrik ALBERT GmbH: office@albert.at